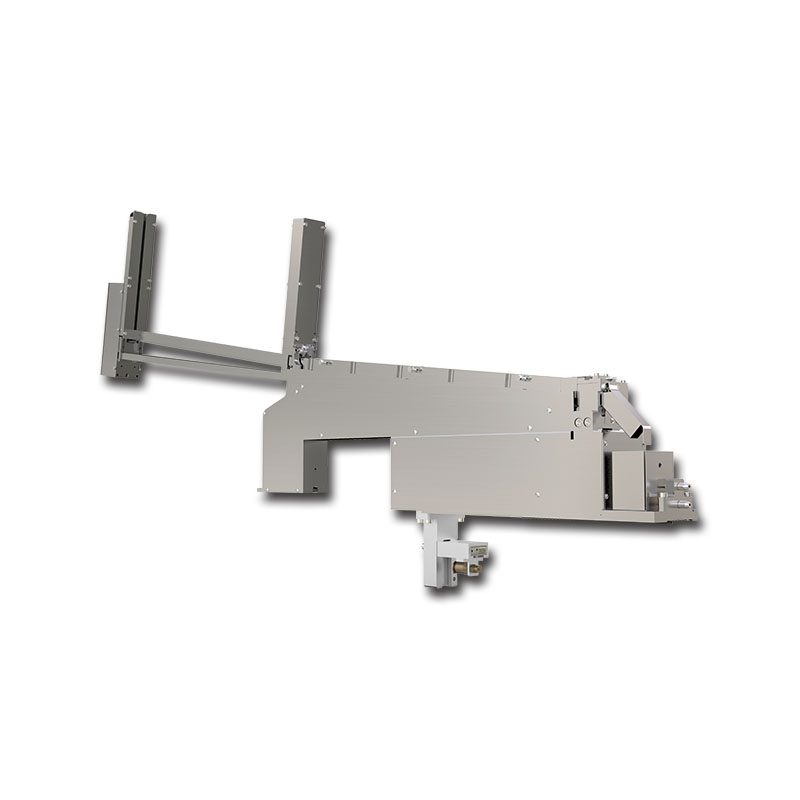

222 tube feeder

222 tube feeder is a feeding machine that transports materials through pipelines to the designated picking location of the plug-in machine. Through the tube feeder, fully automatic and controllable fe

222 tube feeder is a feeding machine that transports materials through pipelines to the designated picking location of the plug-in machine. Through the tube feeder, fully automatic and controllable feeding is achieved, which can completely replace the manual plug-in on the PCB board when used in conjunction with the plug-in machine. Mainly suitable for materials with regular surfaces and high requirements for consistency of material legs. Within the allowable range, feeder can customize according to different customer needs.

Specialties

1) Feeder adopts a combination of motor drive, pneumatic drive, and photoelectric sensor for feeding. It has the characteristics of fast feeding speed and good feeding stability.

2) Compared to conventional bowl feeder, the tube feeder has the advantages of small space occupation, small material deformation, zero reverse probability, and is lightweight. It can achieve quick wire replacement when plugged in and out of the plug-in machine.

3) Compared to ribbon materials, the cost of incoming materials is low and the space occupied is relatively small.

4) Feeder has simple control, is fast and easy to operate for beginners, reduces customer labor costs, and improves customer production efficiency.

5) Feeder has a low failure rate, simple maintenance, and customers have low maintenance costs in the later stage.

Element

Feeding method: pneumatic+electric

Feed efficiency: 0.8-1.0 Sec/Pcs

Weight: 11Kg

Power: DC24V

Air: above 0.4MPa

Current: 4A

Torque: 1.5N/m

Material loading requirements

1) The material is a tube material

2) The loading direction should be foot down, and the foot should not be under force

3) The material cannot be overturned or misaligned inside the tube, and can slide inside the tube

4) Minimize the gap between the material and the inner wall of the material pipe while ensuring sliding of the material inside the pipe