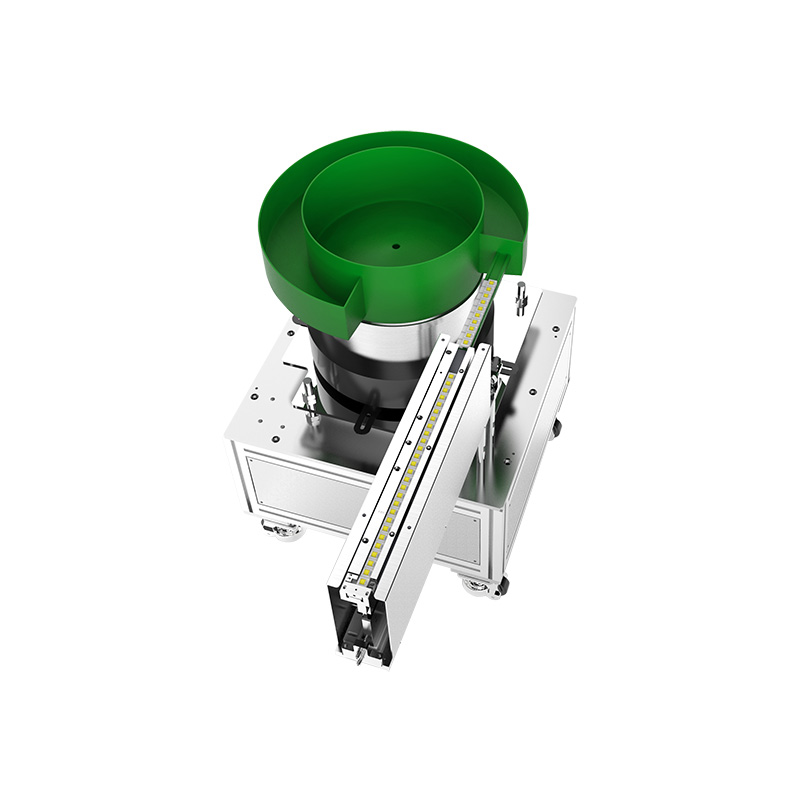

233 bowl feeder

233 bowl feeder is a single disc, double material, and double feeding track feeder. This product can be used on plug-in machines and can meet the needs of two different lengths of materials produced by a single disc.

233 bowl feeder is a single disc, double material, and double feeding track feeder. This product can be used on plug-in machines and can meet the needs of two different lengths of materials produced by a single disc. It has good single disc compatibility, strong material separation purpose, and can be customized according to the required incoming materials.

Specialties

1) This model of vibrating disc is designed with dual tracks, which can deliver materials with the same width and height, but different lengths;

2) The feeding track adopts a direct vibration and photoelectric sensor for feeding, with fast feeding speed. The feeding track can customize start stop, alarm and other actions according to customer needs;

3) The size of the disk and the track can be customized according to the incoming materials, and are generally suitable for materials that are not easily deformed.

Element

Working principle: pneumatic+electric

Weight: approximately 260Kg (subject to final assembly results)

Power supply: AC220V, DC24V

Air source: 0.5-0.65Mpa (clean and free of impurities)

Power: approximately 150-1000W (depending on disk size)

Specifications

Outline dimensions: 570mm (L) x 1500mm (W) x 960mm (H) (subject to final design dimensions)

Working height selection: 750MM/900MM

Discharge speed: not less than 100PCS/minute

Discharge speed: approximately 1.5S~2S/PIN (double take)

Refueling time: approximately 0.5H (depending on the quantity of material in the tray and the size of the tray)

Station occupancy: 2

Incoming material requirements

1. The material is supplied in bulk.

2. The pins of the material are not easily deformed to avoid track jamming.

3. The material body is not easily deformed or damaged.

4. A single material with an overall dimension tolerance of ± 0.3 and a pin pitch tolerance of ± 0.2. If there are shared materials and dimensions that exceed the tolerance, they need to be re evaluated.

5. Two types of materials are required to have the same width and height, and the length of small materials is about 1/3-1/2 of the length of large materials.